What is meant by Printed Electronics?

Printed electronics is a cutting-edge technology that uses printing methods to create electrical circuits and devices. This technology is revolutionising the way electronic components are manufactured by enabling flexible, lightweight, and cost-effective alternatives to traditional rigid circuit boards. But what exactly does printed electronics entail, and how is it shaping the future of technology?

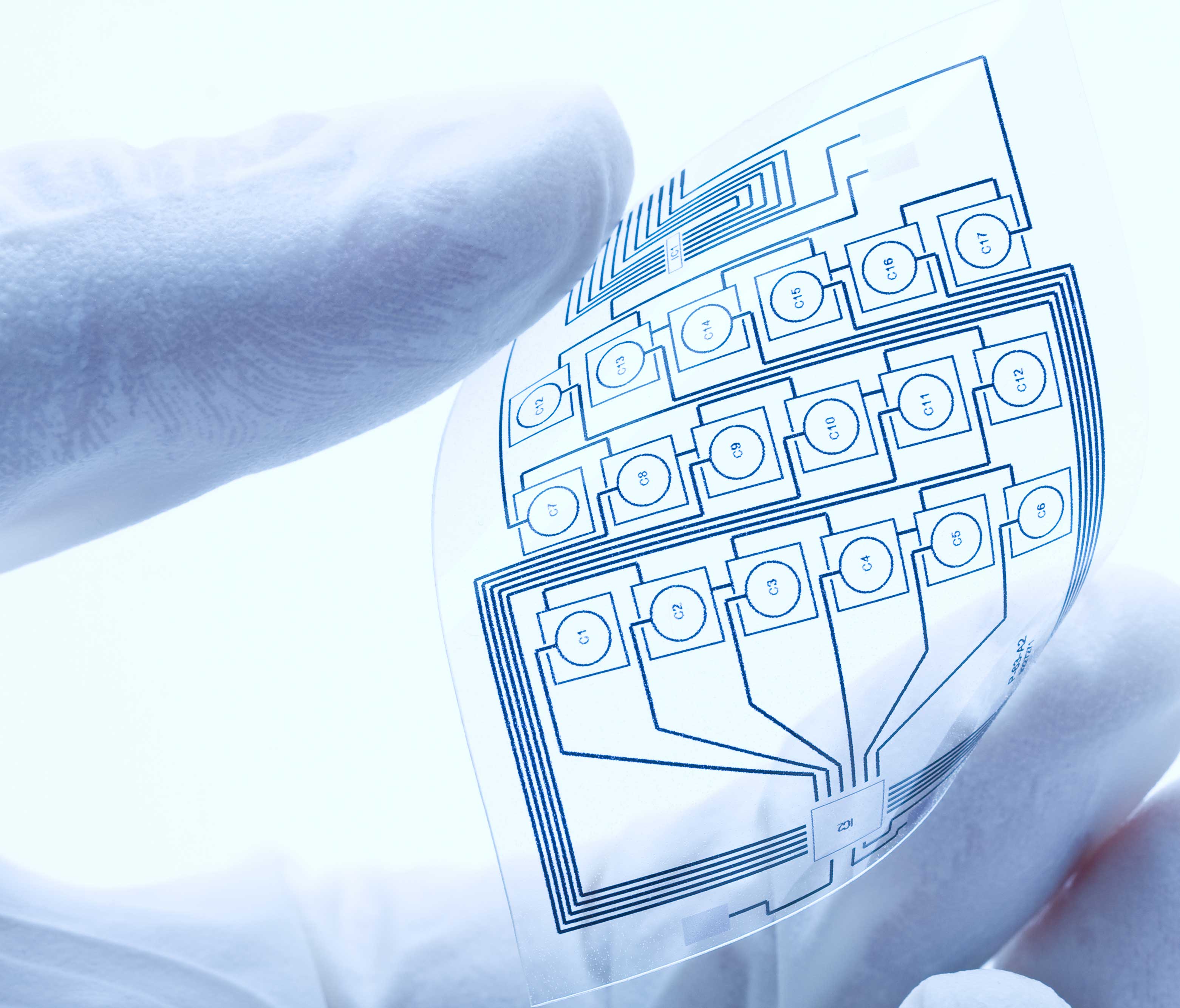

How Do Printed Electronics Work?

Printed electronics is a cutting-edge technology that uses printing methods to create electrical circuits and devices. This technology is revolutionising the way electronic components are manufactured by enabling flexible, lightweight, and cost-effective alternatives to traditional rigid circuit boards. But what exactly does printed electronics entail, and how is it shaping the future of technology?

These printed circuits can be used in various applications, from flexible displays and sensors to smart packaging and medical devices.

Key Components of Printed Electronics

- Conductive Inks: Specialised inks that contain conductive materials like silver, copper, or carbon are used to print the circuits. These inks are designed to carry electrical current through the printed pattern.

- Substrates: The material onto which the ink is printed, typically flexible and lightweight, such as plastic films, paper, or textiles. This allows the circuits to be bendable and adaptable to various shapes and surfaces.

- Printing Techniques: Methods like screen printing, flexography, and inkjet printing are used to precisely deposit the conductive inks onto the substrate in the desired patterns, forming circuits.

Benefits of Printed Electronics

One of the key advantages of printed electronics is its flexibility, both in terms of physical design and manufacturing. Unlike traditional rigid electronics, printed electronics can be applied to curved or flexible surfaces, opening up new possibilities in wearable tech, smart textiles, and foldable devices.

Additionally, printed electronics offer cost advantages due to lower material usage and more streamlined production processes. Since large-scale printing techniques can be used to create electronic components, mass production is more cost-efficient compared to traditional electronic manufacturing.

Other benefits include:

- Lightweight Design: The thin, flexible nature of printed electronics allows them to be integrated into lightweight applications like labels, packaging, or even wearable devices.

- Customisability: Printed electronics can be easily customised for specific applications, making it easier to produce unique or specialised products.

- Environmental Impact: The reduction of bulky components and the potential for more sustainable materials in printed electronics contribute to a lower environmental footprint.

Applications of Printed Electronics

Printed electronics are rapidly gaining traction across a range of industries. Some of the most notable applications include:

- Smart Packaging: Printed electronics can be integrated into packaging to provide interactive features, such as RFID tags, temperature sensors, or even displays that change in response to environmental conditions.

- Wearable Devices: From fitness trackers to smart clothing, printed electronics are making wearable technology more comfortable and versatile, thanks to their lightweight and flexible properties.

- Medical Devices: Printed electronics are being used in disposable medical sensors, wearable health monitors, and even drug delivery systems that provide real-time feedback to healthcare professionals.

- Automotive Industry: Printed electronics are enabling innovations in automotive design, from flexible touchscreens to embedded sensors within vehicle interiors.

The Future of Printed Electronics

The future of printed electronics looks bright as research and development continue to expand the capabilities of this technology. As conductive materials and printing techniques improve, the potential applications will broaden, offering more advanced, cost-effective, and sustainable solutions across various industries.

Customark is at the forefront of supplying labels and printed components that utilise cutting-edge printed electronics technology. Whether it's smart packaging or flexible circuits, we can help bring your innovative ideas to life with our expertise in printed solutions.

Conclusion

Printed electronics represents a shift towards more adaptable, cost-effective, and sustainable electronic components. By leveraging innovative printing techniques and conductive materials, printed electronics are shaping the future of everything from smart packaging to medical devices. Customark is proud to offer a range of solutions that integrate this emerging technology into your business.

For more information on how Customark can support your printed electronics needs, visit our website or contact us directly.