Printed Electronics

Customark provides a rapid reacting, high quality services using our ZERO tooling capability. Our customers are provided with competitive pricing for both prototyping and production.

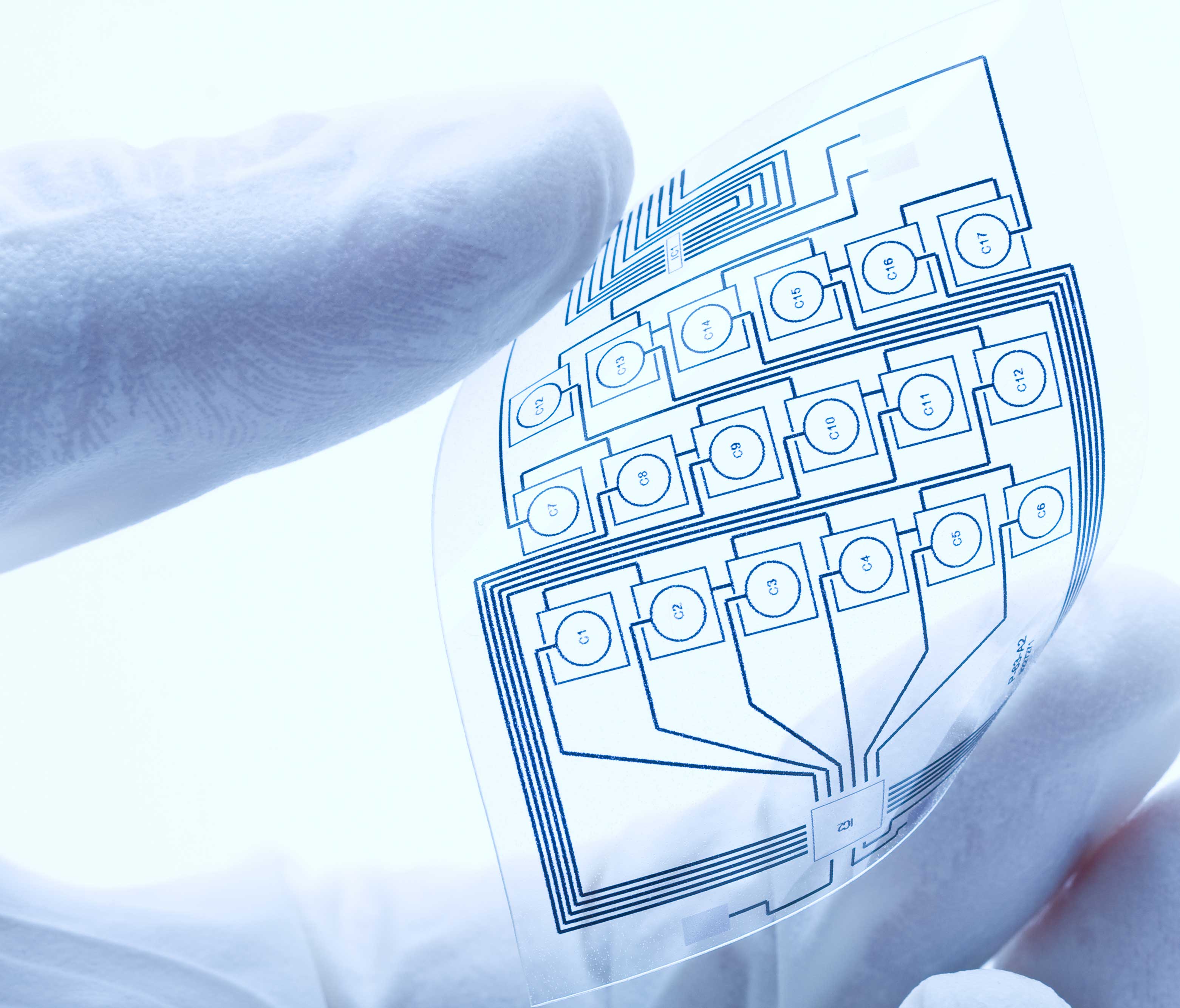

Printing onto electronics is one of the highest growing technologies. Also referred to as flexible circuits, they are commonly screen printed onto a thin flexible substrate and used in membrane keypads for the switching circuits with a tail or ‘fpc’ protruding for connecting via tracks to a PCB.

GET IN CONTACT WITH OUR CUSTOMER SUPPORT STAFF TODAY!

Looking for Printed Electronics?

Contact our customer support staff today!

More on Printed Electronics

The process requires a conductive ink, in our case pure silver, to be printed in tracks onto the thin film. The film is generally between 0.075mm to 0.28mm thick. The most common thickness for us is 0.125mm. The Stencil production is crucial to give the correct track width and quality with the correct deposit on the substrate. The ink has to be cured fully in a very well controlled oven for a specific time and temperature so that the tracks maintain relatively low resistance without losing their flexibility.

Printed electronics is a low cost option with incredible flexibility not just in design but function. Printed electronic circuits can be formed to specific geometry and adhered to the back of complex surfaces. The circuits are commonly designed for capacitive touch or populated with LEDs and switches. The introduction of printed electronics has helped in shrinking the design of products such as mobile phones.

We are now seeing printed electronics introduced into non-conventional applications such as clothing, IoT wiring devices and even furniture. The market is expanding rapidly.

One of the most recent developments is use in In Mould Structured Electronics (IMSE) which is an advancement on in mould decoration, mainly used by the Automotive industry. The printed electronics are placed in the cavity of the plastic injection mould tool so becoming an integral part of the finished moulding.

Printed Electronics are making everyday objects smart.

See what our clients have to say

CONTACT US

TEL: 01384 264700 | FAX: 01384 264729 | Email: Sales@customark.co.uk

"*" indicates required fields

LOOKING FOR SOMETHING ELSE?

Why not check out our other products: